-40%

Terävä Jääkäripuukko 110, Carbon Steel

$ 34.84

- Description

- Size Guide

Description

Terävä Jääkäripuukko 110, Carbon Steel.No fancy bullshit, the Jääkäripuukko is simply a proper no-nonsense utility knife. These come in various sizes. Jääkäripuukko 110 is an excellent all-round knife for just about any tasks, it's best paired up with something bigger such as an axe or the Skrama. Quality carbon steel, traditional Finnish puukko blade profile with a slight drop point. The Jääkäripuukko is not designed to sit on a shelf for decoration, this is an honest tool made for hard work.

Medium size general purpose utility knife, a solid choice for most situations.

Traditional puukko-style blade profile with drop point.

High scandi-style grind with secondary microbevel.

Spine ground and beveled to strike sparks from ferro rods.

Full/stick hybrid tang with textured overmolded rubber grip.

Protruding bare tang head with lanyard hole.

Technical specs

Specs

Metric

Imperial

Weight (knife only)

175 g

6.20 oz

Total length

240 mm

9.4"

Blade length

110 mm

4.3"

Blade thickness

4.20 mm

0.17"

Edge angle

23°

Steel

80CrV2, 59 HRC

Blade

Traditional and proven functional Finnish puukko profile with a drop point. The thickness of 4,2 mm / 0.17" makes this a bit more robust than most old-timey traditional Finnish puukkos. The profile is a Scandi grind with a tiny secondary bevel, currently the most commonly used style in Finnish puukkos.

The strong blade can take a beating, you can use the Jääkäri for batoning without a problem, just don´t hit your fingers, unless yours are strong like steel.

80CrV2 carbon steel and heat treatment

All Terävä carbon steel knives are made from 80CrV2. The "thing" is that this is really nothing fancy or special, just very good tool steel which can take a beating and offers good edge retention. 80CrV2 has over the decades earned a reputation as solid and reliable steel, especially for our purposes.

The heat treatment we use leaves the surface of the steel softer (approx. 52 HRC) than the inside (59 HRC). This functions a lot like fancy differential heat treatments giving the blade added strength. The surface is very resistant against any microscopic fractures or other blemishes, this results in virtually zero problems caused by material defects!

When the blade is ground the harder inner steel is revealed, even though the outer surface is only 52 HRC the actual edge is 59 HRC. This is also why we grind bevels onto the sides of the spine, otherwise, the spine corners would not be hard enough to strike sparks from ferro rods!

Carbon steel requires care: if your knife gets wet in the bush, dry it the best you can. Never store the knife without drying and oiling the blade.

Grip

The rubber grip is somewhat ergonomically shaped, but not one of those crazy finger groove things. A small finger guard on the front, a little belly in the middle and a knob at the back to keep your hand from slipping and also make it possible to use a Leuku style chopping grip.

The tang runs all the way through the grip and comes out the back, forming a little knob with a hole in it for lanyards and such. The knob can also be used to hit things, naturally.

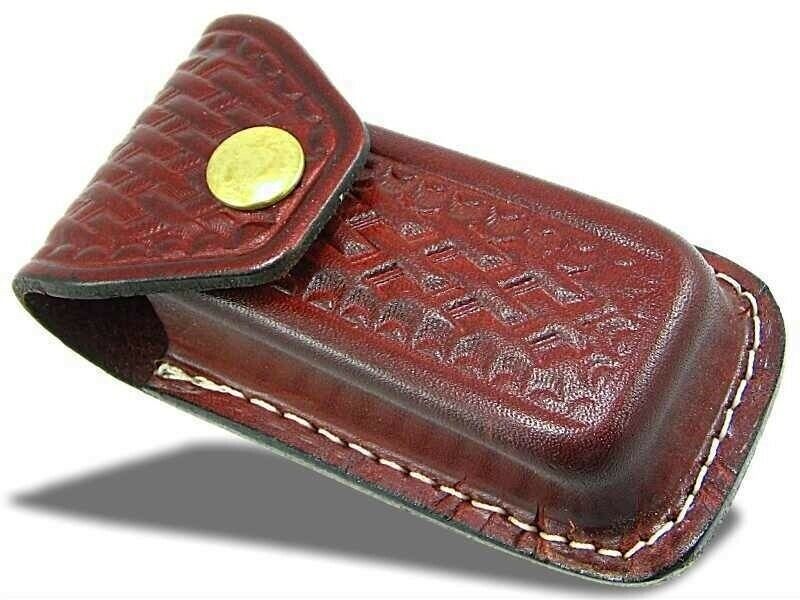

Leather sheath

The sturdy dangler leather sheath is built with a roomy plastic liner, traditional Finnish sheath construction style. The liner is roomy enough for water and crud to run through it and out the hole at the end. Around the mouth of the sheath, the leather is folded double forming a strong and stiff wide band, this band is closed tightly around the grip using a press stud. When you pull out the knife the edge runs nicely between the two leather sides, not cutting it up as is a common downside of the traditional "sock" style puukko sheaths. Even without closing the press stud the sheath retains enough tension to keep the puukko in place, so around camp, you don´t need to be opening and closing the sheath all the time, just remember to snap it shut when you're on the move!

Do not force the knife out of the sheath without opening the press stud!

Although this can be done it is not good for the press stud in the long run and may damage it. Just open the snap before pulling out the knife.

It's best to oil the snap fastener once in a while to prevent it from becoming stiff and nasty.

Sustainable leather

The leather of Terävä sheaths comes from

Pelo Leather, a family-owned Central Ostrobothnian tannery

founded in 1897. In addition to producing top-quality sheath and nappa leathers with a minimized waste of materials and emissions, they are respectful towards the source of the raw materials: the animals as well as the nature in which they live.

Pelo Leather uses elk and yak hides provided by hunters and nomads, and only cowhides that are a side-product of the milk and meat industries. The cowhides come from local abattoirs who have standards for ensuring the wellbeing of the animals. No animals are reared for the purpose of producing these leathers.

Their business quarter is 25 years and a lot of effort is put into the processes and logistics of the business, to provide a cleaner environment for future generations. We tip our hats at them and are proud to have their leather in our sheaths!

A few words from the designer

The basic idea for the Jääkäri was very simple: to make a functional knife with all the pros and none of the cons of a traditional Finnish puukko. A traditional puukko is fine, but the rat tail tang, wooden grips and floppy sheaths are not exactly the most practical designs anymore. So we made the blade strong, 4 mm thick, and with a full tang that goes all the way through the grip. The handle is shaped for a good grip and made from rubber.

The basic leather sheath is nothing like it's wildly swinging ancestors, this one is made with a sturdy turning belt loop and a press stud to secure the knife in place.

This is not rocket science really, but just a simple good puukko for real use. Nothing fancy, works like a charm!